Construction design of prefabricated buildings

Classification:

Engineering

Key words:

Engineering

Construction design of prefabricated buildings

Product Description

Prefabricated buildings, prefabricated housing manufacturers, prefabricated high-rise residences, prefabricated high-rise office buildings, prefabricated hotels

Implement GBT51232-2016 Technical Standards for Prefabricated Steel Structure Buildings, (GB 50936-2014 Technical Specifications for Concrete-filled Steel Tube Structures), Relevant National Atlases (Steel Structure Housing II, Approval No. Jianzhi (2005) No. 201, Unified No. GJBT-884), JGJ/T421-2018 Technical Standard for Cold-Formed Thin-walled Steel Multi-storey Housing, JGJ 227-2011 Technical Regulations for Low-rise Cold-Formed Thin-walled Steel Houses, and Other Special-shaped Component Standards, MS light steel lattice cast-in-situ (or prefabricated) foam concrete composite walls can also be applied to European and American standards.

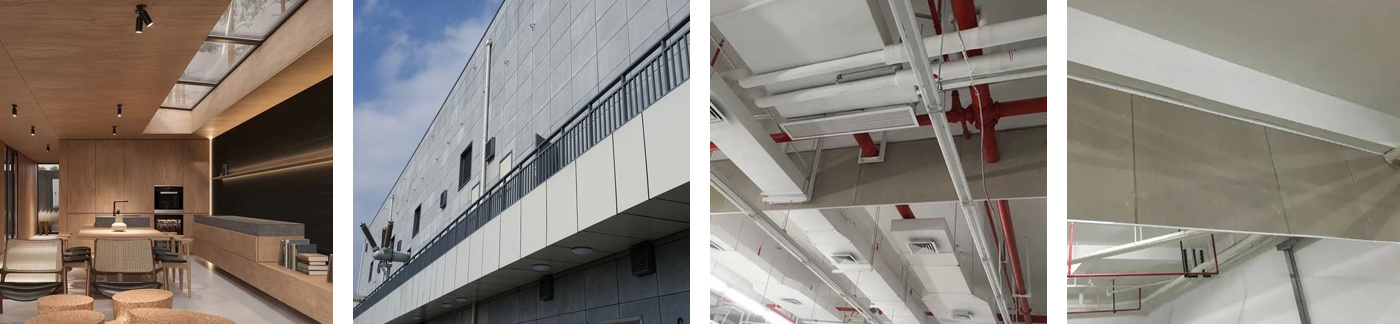

Prefabricated buildings mainly include prefabricated concrete structures, steel structures, modern wood structure buildings, etc., because of the use of standardized design, factory production, assembly construction, information management, intelligent application, is the representative of modern industrial production mode. With the development of modern industrial technology, the construction of houses can be made in batches and sets, just like machine production. As long as the prefabricated house components are transported to the construction site and assembled, it is done.

1. A large number of building parts are produced and processed by the workshop, and the main types of components are: exterior wall panels, interior wall panels, laminated panels, balconies, air conditioning panels, stairs, prefabricated beams, prefabricated columns, etc.

2. A large number of assembly operations on site are greatly reduced compared with the original cast-in-place operations.

3. Adopt the integrated design and construction of architecture and decoration, and the ideal state is that the decoration can be carried out simultaneously with the main construction.

4. The standardization of design and the informatization of management, the more standard the components, the higher the production efficiency, the corresponding component cost will decrease, and with the digital management of the factory, the cost performance of the entire prefabricated building will be higher and higher.

5. Meet the requirements of green buildings.

6. Energy saving and environmental protection

Fields of application

It can be applied to multi-storey, high-rise, super high-rise and other buildings, residential, commercial, office buildings, office buildings, libraries, archives, science and technology museums, cinemas, hospitals, nursing homes, nursing homes, star-rated hotels, star-rated hotels, business hotels, and other construction fields can be applied, and the drawing review and project acceptance are in line with national standards. Its characteristics are rigid and flexible, steel structure, reinforced concrete structure and thermal insulation fireproof concrete wall are integrated, the exterior does not leak steel, and the steel is wrapped in cement, which will never rust and prolong the service life of the steel structure. The thickness of the wall concrete reaches 30-50mm, which can be nailed, hung, expanded bolts, sound insulation, heat preservation, waterproof, fire prevention, seismic resistance, wind resistance, anti-corrosion and other indicators exceed the national standard, which is the preferred technology for passive house construction, with an overall life span of more than 100 years, and standardized factory production can ensure stable quality. The construction period is more than doubled, in line with the industrial policy, and can enjoy state subsidies. It can be designed, produced and constructed according to different styles around the world, and is suitable for any country and region. Because of its structural properties, it is an inorganic material, which can be matched with various decorative materials, and solves the problem of cold and hot bridges in the steel structure maintenance system. The formation of inorganic vacuum maintenance system, eliminate the cold and hot aisles, but also increase the air tightness, solve the problem of anti-corrosion, water, electricity and heating pipelines can be buried in the wall and the ground. In the field of green building energy saving, the company has developed a green energy integrated application platform (five constant systems: constant temperature, constant humidity, constant oxygen, constant static, constant clean), and adopts the dynamic design method of mechatronics to achieve the effect of comfort and energy saving.

Our company from design, production, construction to turnkey full range of services, domestic and foreign can undertake business, can also provide technology and materials, by the customer to build, the construction cost is not affected by the distance of the project location.

Packed and shipped

Widely used in construction, decoration, home and other fields, welcomed by the market, the company currently covers an area of 60,000 square meters, production plant 15,000 square meters, equipment using Germany Siemens PLC automation process, quality and production capacity ranked first in the country, products to meet the national advanced standards.

Appearance of the factory

Dezhou Dingyao Environmental Protection Building Materials Co., Ltd. was established in 2009 with a registered capital of 20 million yuan. The company's predecessor has been engaged in prefabricated green building design, construction, and material production since 2002. It is engaged in architectural design, construction, material production, and building energy-saving technology research. An enterprise integrating development, development, production and sales, the company has strong technical force, with 5 senior engineers, 15 engineers, and more than 200 employees.

VIDEO

online message